Hydraulic breakers are the heartbeat of modern construction, mining, quarrying, and demolition projects, and their reliability heavily depends on the quality and maintenance of three essential components such the chisel (tool), piston, and seal kits. These parts determine the breaker’s impact power, efficiency, uptime, and overall lifespan. Whether you operate a compact mini excavator hydraulic breaker or a heavy-duty hammer for mining, replacing worn components at the right time is crucial to ensure continuous and safe operation.

For owners and users of the Beilite BLT Series hydraulic breakers, understanding how these parts function, when to replace them, and how to maintain them properly, these can dramatically reduce downtime and repair costs. As Beilite machinery continues to expand globally with strong demand for hydraulic rock breaker parts, high-quality replacements have become more important than ever.

Why Hydraulic Breaker Parts Matter?

Every hydraulic hammer depends on precise engineering. The constant high-frequency impact creates significant stress on internal components. Over time, even the strongest steel and seals experience fatigue. A hydraulic breaker with a damaged chisel, worn piston, or leaking seal kit loses efficiency quickly. Fuel consumption rises, impact power decreases, and the risk of catastrophic internal damage increases.

Beilite hydraulic breakers known for their powerful impact force, well-tempered steel structure, and advanced MIC noise-reduction technology perform at their best only when maintained with high-quality spare parts. Replacing components on time is not just routine maintenance; it is a critical part of protecting your investment.

Hydraulic Breaker Chisels: When and Why Replacement is Needed?

The chisel or working tool is the most visible and frequently replaced hydraulic breaker part. It takes the full force of every blow and channels the energy into rock, concrete, or asphalt. Over time, chisels naturally lose length, shape, and hardness due to repeated impact. When a chisel becomes blunt, mushroomed, or cracked, productivity drops sharply.

Worn chisels increase stress on the piston and bushings because the hammer must work harder to achieve the same breaking effect. Operators may also notice overheating or unusual vibration. Regularly inspecting the working tool is one of the simplest ways to maintain breaker efficiency. When it’s time for replacement, using a high-quality Beilite chisel ensures proper hardness, correct dimensions, and long-working life, preventing additional internal wear.

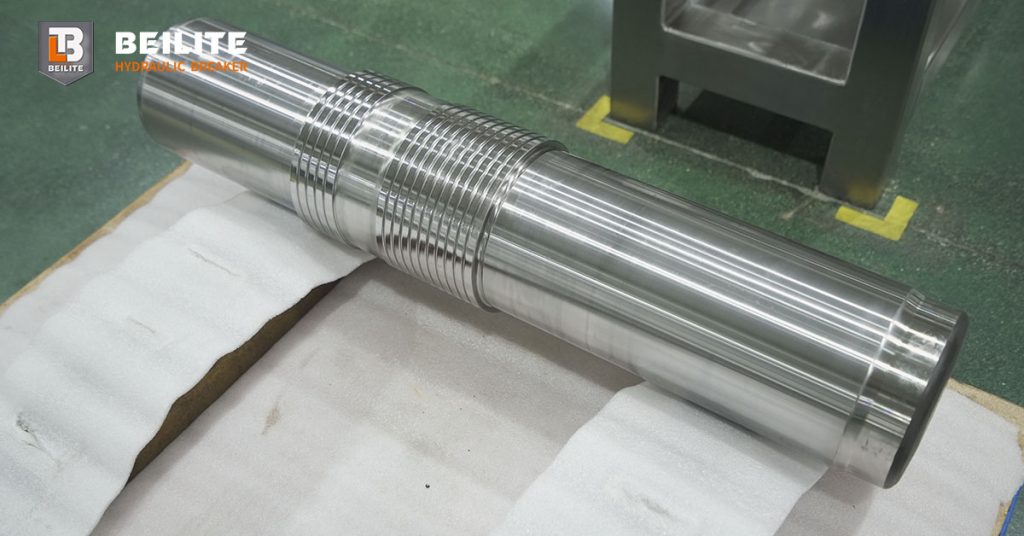

Hydraulic Breaker Pistons: The Heart of the Hammer breaker or Rock Breaker

If the chisel is the blade, the piston is the heart of the hydraulic breaker. It delivers every impact blow and must remain perfectly balanced, polished, and free from cracks or deformation. Contamination in hydraulic oil, improper lubrication, misalignment, and overheating are common causes of piston wear.

A damaged piston creates serious internal friction, which can quickly lead to cylinder scoring, loss of power, or complete failure of the hydraulic breaker. Because the piston is precisely matched with the cylinder and seal system, replacing it with a compatible Beilite hydraulic breaker piston is essential. Genuine pistons are manufactured with exact heat-treatment processes and tolerances, ensuring smooth impact cycles and optimal power transmission.

Timely replacement of worn pistons not only improves performance but also protects high-value components like the front head, back head, and cylinder body. For operators in heavy industries such as mining, quarrying, and concrete demolition, piston health should be checked regularly as part of preventive maintenance.

Seal Kits: Small Parts with a Huge Impact

Among all hydraulic breaker parts, seal kits may appear minor, but they are some of the most critical components for operational reliability. Seals prevent oil leaks, maintain pressure, protect the piston from contaminants, and ensure the hammer cycles correctly. Even a slight seal failure can lead to overheating, weak impact power, slow striking, or complete breakdown.

Harsh working environments dust, moisture, high temperatures—can degrade seal materials over time. Low-quality hydraulic oil also accelerates wear. When users begin to notice abnormal oil consumption, reduced power, or internal leakage, a Beilite breaker seal kit replacement is often necessary. Using the right seals ensures correct fitment, oil compatibility, and resistance to high-impact pressure.

Routine replacement of seal kits is one of the most cost-effective ways to extend a breaker’s lifespan. Many contractors choose to replace seal kits every six months or after heavy-use cycles, depending on site conditions.

Why Choose Genuine Beilite Replacement Parts?

Using genuine Beilite replacement parts chisels, pistons, and seal kits ensures that each component meets the manufacturer’s specifications. Low-quality aftermarket parts often have incorrect hardness, poor machining accuracy, or incompatible materials that can cause internal damage. Genuine parts not only last longer but also reduce maintenance downtime.

Beilite’s BLT Series offers a wide range of breaker models from BLT-40 for mini excavators to BLT-280 for heavy-duty machines. Each model requires precisely sized components. Choosing authentic Beilite hydraulic breaker parts ensures correct fitment, stable performance, and consistent strike force.

Another key advantage is the availability of strong global after-sales support. Whether you are in Southeast Asia, the Middle East, Africa, or Europe, Beilite’s distribution network provides quick access to spare parts, technical support, and professional service guidance.

Practical Tips for Extending the Life of Breaker Parts

Daily maintenance plays a huge role in the lifespan of chisels, pistons, and seals. Proper lubrication of the chisel reduces friction and bushing wear. Monitoring hydraulic oil quality helps maintain piston and cylinder integrity. Regular inspection ensures early detection of cracks, overheating, and alignment issues. Operators should also avoid blank firing, as it accelerates wear on all components.

Taking these basic steps significantly reduces the frequency of part replacement, and ensures the hydraulic breaker delivers maximum impact energy on each stroke.

Conclusion

Whether you are operating a Beilite hydraulic breaker for quarrying, mining, demolition, or infrastructure construction, the condition of your chisel, piston, and seal kits will determine your productivity and long-term equipment reliability. Genuine Beilite replacement parts provide the strength, durability, and precision required to keep your hydraulic hammer performing like new.

By understanding when and why these parts need replacement, and by following proper maintenance, you can extend the working life of your breaker and avoid costly downtime ensure smooth and powerful breaking performance on every job.

Frequently Asked Questions (FAQs)

1. How do I know when my hydraulic breaker chisel needs to be replaced?

A chisel should be replaced when it becomes excessively blunt, shortened, cracked, or mushroomed at the tip. Operators will also notice slower penetration, higher vibration, and increased fuel consumption. A worn chisel transfers unnecessary stress to the piston and bushings, so timely replacement prevents larger internal failures and keeps your Beilite hydraulic breaker working efficiently.

2. What causes hydraulic breaker pistons to wear out faster than expected?

Premature piston wear is usually caused by contaminated hydraulic oil, poor lubrication, misaligned bushings, or frequent blank firing. Working in extremely dusty or abrasive environments can also accelerate wear. Using genuine Beilite pistons ensures proper hardness, machining accuracy, and thermal treatment, which helps maintain strong impact power and extends the life of the entire hammer.

3. How often should seal kits be replaced in a hydraulic breaker?

Seal kit lifespan varies based on usage intensity, working environment, and oil quality. In heavy applications such as quarrying or mining, seals may need replacement every 6–12 months. If you notice internal leaks, reduced impact energy, overheating, or slow striking, it is likely time to replace the seal kit. Genuine Beilite seal kits are designed for high-pressure resistance and longer working life.

4. Where can I buy genuine Beilite hydraulic breaker parts?

Beilite Machinery supplies genuine chisels, pistons, and seal kits through an international dealer network, including Southeast Asia, the Middle East, Africa, South America, and Europe. You can contact your local distributor or reach/contact Beilite headquarters directly for parts support, technical assistance, or model verification. Buying authentic Beilite parts ensures proper fitment and protects your hydraulic breaker from damage caused by incompatible aftermarket components.

Beilite Machinery Co., Ltd.

40008-40008

info@beilite.com

+6282321982255

English

English Indonesian

Indonesian