Hydraulic breakers or hydraulic hammers are crucial excavator attachments for demolition, quarrying, mining, road construction, and general infrastructure construction. These reliable hydraulic hammers are long-term performance lie in the quality and maintenance of components, particularly the hydraulic breaker bolts and hydraulic breaker spare parts. A well-maintained hydraulic hammer ensures higher impact power and minimize downtime.

Why Hydraulic Breakers Bolts Are Critical?

Hydraulic breaker bolts (for example tie rods, side bolts, front head bolts, back head bolds, O-rings, bushings) are essential to keep the hydraulic breaker body tightly assembled under constant, high-frequency impact. When bolts fail or stretch due to stress, symptoms like unusual vibrations, oil leaks, misalignment, and reduced striking power emerge. As consumable spare parts, bolts must be regularly inspected and replaced. Using poor-quality bolts risks severe damage, including piston breakage, front head cracking, oil leakage or complete hydraulic hammer failure.

Why Choose Beilite Hydraulic Breakers Spare Parts?

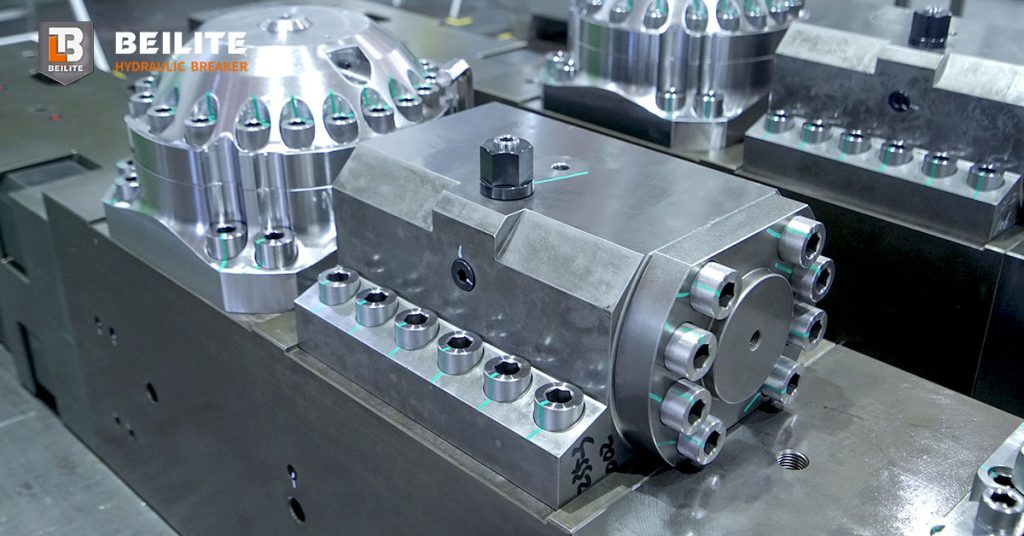

Beilite is a global leader in excavator attachments and premium heavy-duty hydraulic breakers, known for precision engineering and advanced heat treatment. Choosing Beilite hydraulic breaker spare parts provides you clear operational advantages:

1. High-Strength Alloy Bolts: Made with strengthened alloy steel to resist stretching and loosening during heavy-duty operations.

2. OEM-grade Compatibility: Spare parts (including pistons, cylinder bushings, seal kits, chisels, and accumulators etc.) are precision-designed for accurate fitment on Beilite rock breaker models and many OEM cross-compatible hammer breakers.

3. Cost-Effective Durability: Beilite maintains strict quality standards, offering a more durable and cost-effective alternative to many high-end brands.

4. Global Availability: Hydraulic breakers spare parts are readily available from distribution centers in Asia (Beilite Indonesia Branch), Beilite Official China Mainland, Europe, Africa, South and North America, and the Middle East (Beilite Saudi Arabia Branch), ensuring quick access to replacement wear parts.

Key 6 Beilite Hydraulic Breaker Spare Parts for Longevity Work

Focus maintenance on these critical components to ensure stable, low costs and long-term performance:

| Component | Function |

| Hydraulic Breaker Bolts (Tie Rods/Side/Front) | Keep the hydraulic hammer tightly assembled; prevent vibration damage. |

| Chisel / Tool | The direct impact tool; requires regular inspection for efficient breaking. |

| Bushings (Inner & Outer) | Guide the chisel; worn bushings accelerate costly piston wear. |

| Piston | The heart of the hydraulic breaker; use only OEM-quality replacement units. |

| Seal Kits | Prevents hydraulic oil leakage; maintains consistent impact pressure. |

| Accumulator | Stores nitrogen gas to maintain energy efficiency and protect components from pressure shock. |

Top 6 Maintenance Guide to Extend Hydraulic Breaker Lifespan

Regular appropriate maintenance is paramount for maximizing your Beilite rock breaker’s lifespan:

1. Lubricate Frequently: Use proper chisel grease as recommended by manufacturer to minimize wear between the tool and bushings. Auto-greasing is recommended for demanding applications.

2. Inspect Bolt Tightening: Check tie rod and side bolt torque daily with a torque wrench to prevent structural stress and failure.

3. Replace Worn Bushings: Early replacement prevents expensive damage to the piston and front head.

4. Avoid Dry Firing: Always ensure the tool is firmly pressed against the material before activating the hammer.

5. Follow Gas Charging: Maintain correct nitrogen pressure according to the technical manual for stable impact power.

6. Use Genuine Spare Parts: OEM Beilite parts guarantee correct fitment, hardness, and durability.

Summary:

Timely bolts maintenance and replacement of hydraulic hammer spare parts are crucial for safety and powerful operation. By choosing Beilite hydraulic breakers and OEM-quality spare parts, operators should should benefit from superior durability, reduced operation costs, and reliable performance across demanding applications like concrete demolition and secondary rock breaking.

Keywords

- Primary Keywords: hydraulic hammer, hydraulic breaker, rock breaker, breaker bolts, spare parts, excavator attachments.

- Component Keywords: tie rods, side bolts, front head bolts, chisel grease, piston, bushings, seal kit, accumulator, nitrogen pressure.

- Application Keywords: demolition, quarrying, mining, road construction, concrete demolition, secondary rock breaking, hammer failure.

- Brand Keywords: Beilite, OEM-grade, wear parts, striking power.

Frequently Asked Questions (FAQs)

1. How often should I check or replace my hydraulic breaker bolts?

Hydraulic hammer or hydraulic breaker bolts are consumable parts under constant stress and should be inspected and checked for correct torque daily. Replacement frequency depends heavily on the application’s severity, but any bolt showing signs of stretching, damage, or an inability to hold torque must be replaced immediately to prevent catastrophic hammer failure.

2. What is “dry firing” and why should I avoid it?

“Dry firing” is operating that the hydraulic hammer when the chisel/tool is not firmly pressed against the breaking material. This sends excessive shock and stress back through the piston and internal components, leading to rapid wear of the bushings, seals, and potentially causing premature piston breakage. Always keep pressure on the material before activating the breaker.

3. Are Beilite hydraulic breaker spare parts compatible with other hydraulic hammer brands?

Beilite spare parts are designed for optimal performance on Beilite hydraulic breakers. However, many key components, such as bushings, seal kits, and chisels, are engineered for OEM-grade compatibility and can often be used as high-quality, cost-effective alternatives on many major cross-compatible breakers. Always verify the part number and specifications for accurate fitment before purchase.

Beilite Machinery Co., Ltd.

40008-40008

info@beilite.com

+6282321982255

English

English Indonesian

Indonesian