Hydraulic breakers—especially on mini, medium, and heavy excavators—are essential for large demolition, trenching, stone breaking, soil compaction, tunnel profiling, difficult soil penetration, hard rock breaking, and infrastructure constructions. But one of the most common problems operators face on job sites is a hydraulic breaker that stops hammering, hammers weakly, or refuses to start striking at all.

This guide provides a practical, field-tested breakdown of the top 12 reasons why a hydraulic breaker is not hammering and how operators can troubleshoot the issue effectively. While the information applies to most brands, the case focus on highlights Beilite hydraulic breakers, known for their stable performance and practical service solutions.

1. Insufficient Hydraulic Flow

Symptom: Breaker barely moves or doesn’t start striking.

Cause: Excavator is not delivering the required oil flow.

Check How to Fix :

- Check the excavator’s auxiliary flow setting.

- Compare with Beilite breaker’s flow requirement listed on the nameplate.

- Adjust the flow or switch to high-flow mode (if available).

2. Incorrect Hydraulic Pressure

Trouble: Weak blows, delayed hammering

Cause: Pressure too low or relief valve improperly adjusted

Check How to Fix :

- Measure system pressure.

- Set pressure to Beilite’s recommended working range.

- Inspect excavator relief valves and pump output.

3. Air Inside Hydraulic Lines

Trouble: Hydraulic Breaker activates irregularly or starts/stops unexpectedly

Cause : Air pockets block hydraulic force

Check How to Fix :

- Bleed air from lines by cycling the attachment control.

- Check hose fittings for looseness or leaks.

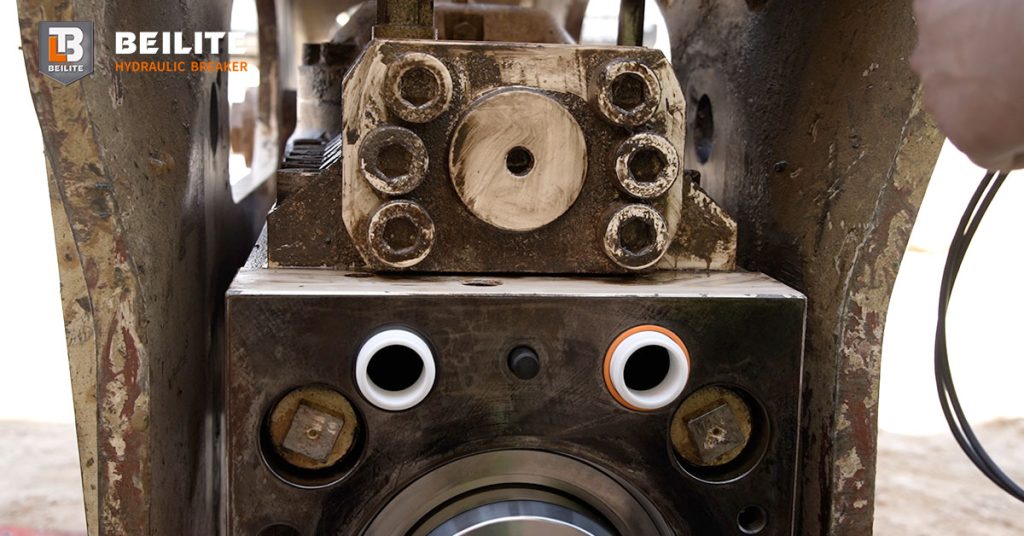

4. Stuck or Damaged Piston

Trouble: No impact even though oil is circulating

Cause: Contamination, lack of lubrication, or internal wear

Check How to Fix :

- Inspect piston through service ports.

- Replace piston seals or rebuild the piston chamber.

- Prevent recurrence by greasing the tool every 2–5 hours.

Beilite can ship piston repair kits and provide a rebuild video guide.

5. Worn Tool Bushings

Trouble: Tool moves excessively but no striking occurs

Cause: Excessive play prevents the piston from transferring energy

Check How to Fix :

- Check front head, back head and tool bushing wear.

- Replace worn bushings using Beilite OEM parts.

- Avoid prying or side-loading the tool.

6. Tool (Chisel) Stuck or Not Fully Inserted

Trouble: Breaker hums but no hammering

Cause: Chisel Tool is not locked, or retaining pins are damaged

Check How to Fix :

- Remove and clean the tool.

- Check retaining pins for wear.

- Reinsert tool fully and secure with new pins if needed.

7. Low Nitrogen Gas Pressure in the Accumulator

Trouble: Soft or weak blows

Cause: Nitrogen leaked or pressure dropped over time

Check How to Fix :

- Test nitrogen pressure using a Beilite service gauge.

- Recharge the accumulator to the recommended value.

- Do NOT use oxygen or compressed air.

8. Blocked or Damaged Oil Filter

Trouble: Breaker starts then stops repeatedly

Cause: Hydraulic oil cannot reach full flow

Check How to Fix :

- Replace the hydraulic return filter.

- Inspect suction filters.

- Use clean hydraulic oil suitable for hammer breaker use.

9. Wrong Oil Viscosity

Trouble: Slow reaction, weak impact, or overheating

Cause: Oil too thick (cold or wrong grade) or too thin (high temperature)

Check How to Fix :

- Warm up the machine before heavy operation.

- Switch to oil grade recommended for the breaker and climate.

10. Broken or Jammed Stop Pin / Front Head Issues

Trouble: Piston cycles but no striking

Cause: Internal components blocking tool movement

Check How to Fix :

- Remove the tool and inspect stop pins, bushings, and lower head.

- Replace broken parts with Beilite OEM components.

11. Contaminated of Hydraulic Oil

Trouble: Rapid wear, piston sticking, slow hammering

Cause: Dirty oil or metal particles

Check How Fix :

- Drain and replace with clean oil.

- Flush lines.

- Replace filters to avoid damaging new parts.

12. Excavator Compatibility Issues

Trouble: Breaker fails shortly after installation

Cause: Wrong hose size, improper return line, incompatible settings

Check How to Fix :

- Ensure free-flow return line (not through main valve).

- Confirm hose diameter fits Beilite requirements.

- Adjust excavator settings to match breaker specifications.

How Operators Can Get Assistance from Beilite

Beilite offers comprehensive support to ensure your breaker performs at full capacity:

1. Technical Diagnosis Support

Operators and buyers are advice to shot or take pictures and send to assistance service team for assistance:

- Photos

- Short videos

- Excavator model

- Breaker serial number

Beilite engineers are available to provide to assistance same-day diagnosis.

2. Spare Parts Supply

OEM parts such as:

- Pistons

- Bushings

- Seal kits

- Accumulator repair kits

- Retaining pins

Hydraulic hammer breakers are shipped in protective packaging with global logistics support.

3. Live Troubleshooting Guidance

Through WhatsApp or video call, Beilite technicians walk operators step-by-step through:

- Disassembly

- Seal replacement

- Pressure adjustment

- Nitrogen charging

4. Compatibility Recommendations

Before installing the hydraulic breaker, Beilite Engineering team confirms:

- Oil flow and pressure range

- Hose size

- Carrier compatibility

- Bracket configuration

This prevents installation errors and cause of non-hammering system are settings appropriately.

Conclusion

A hydraulic breaker that stops hammering is not only frustrating but costly. Most issues come from incorrect hydraulic breaker system settings, worn parts, or irregular improper maintenance. By understanding the top 12 common causes—hydraulic flow problems, pressure issues, nitrogen loss, worn bushings, contaminated oil, or tool installation faults—operators can quickly restore performance.

Beilite hydraulic breakers offer stable performance and provide operators with responsive technical support, OEM parts, and practical troubleshooting guidance. With correct operation and timely maintenance, your breaker will deliver strong, consistent impact power throughout its service life.

Keywords:

Primary Keywords

hydraulic breaker not hammering

hydraulic hammer troubleshooting

breaker not working fix

Beilite hydraulic breaker problems

hydraulic breaker maintenance

Secondary Keywords

excavator breaker not striking

hydraulic hammer weak impact

hydraulic breaker repair guide

breaker not firing solutions

nitrogen pressure for breaker

hydraulic oil flow issues

breaker chisel not moving

piston stuck hydraulic breaker

excavator attachment troubleshooting

Long-Tail Keywords

why does my hydraulic breaker stop hammering

how to fix a breaker that won’t strike

breaker hammer troubleshooting for mini excavators

Beilite breaker service and support

hydraulic breaker accumulator pressure issue

tool stuck in hydraulic hammer

symptoms of low hydraulic flow in excavator attachments

LSI Keywords

breaker startup problems

hydraulic circuit inspection

excavator auxiliary line problems

breaker pressure setting

breaker tool lubrication

OEM breaker spare parts

These keywords are all aligned with the new blog to reach global operators, contractors, and parts buyers.

FAQs

1. Why is my hydraulic breaker not hammering?

Most commonly due to low hydraulic flow, incorrect pressure, air trapped in the hydraulic lines, worn bushings, low nitrogen pressure, or piston blockage. A systematic inspection of the hydraulic system and breaker components is required.

2. What is the first thing to check when a breaker won’t strike?

Start with the excavator’s hydraulic flow and pressure settings. Ensure they match the breaker’s specifications. In the case of Beilite breakers, check the flow chart on the nameplate or request data from Beilite support.

3. Can low nitrogen pressure stop a hydraulic breaker from hammering?

Yes. Low nitrogen pressure in the accumulator significantly weakens or completely stops the hammering motion. Recharging the accumulator with nitrogen often restores performance.

4. Why does my hammer breaker start but stop after a few strikes?

This usually indicates blocked filters, contaminated hydraulic oil, or cavitation caused by air in the system. It may also be a sign of worn seals or internal leakage.

5. What happens if the hydraulic breaker tool (such chisel) is not fully inserted?

An improperly seated tool prevents the piston from transferring impact energy, causing the breaker to hum but not strike. Reinsert the tool and check retaining pins for wear.

6. How do I know if the piston is stuck?

A stuck piston will cause complete loss of impact despite stable oil flow. You may hear the breaker running but without strike. A teardown is required to inspect the piston, bushings, and chamber.

7. How often should I grease the hydraulic breaker?

Every 2–5 hours of continuous operation. For Beilite breakers, operators should use high-temp grease to reduce bushing wear and prevent piston misalignment.

8. Will wrong oil viscosity stop the breaker from working?

Yes. Oil that is too thick (cold) or too thin (hot) affects breaker reaction and can cause weak or intermittent hammering. Always use the recommended oil grade.

9. Can I get technical help from Beilite if the breaker is not hammering?

Absolutely, Beilite Maintenance Assistance Team provides Complete Guide:

Video/WhatsApp diagnosis

Flow/pressure setting guidance

Service manuals

OEM spare parts (pistons, bushings, seal kits, accumulators)

They respond quickly with practical operational solutions.

10. How do I prevent my breaker from suddenly stopping on the job?

Operators and Buyers should follow these preventive tips:

Maintain correct oil flow & pressure

Grease frequently

Keep hydraulic oil clean

Avoid side-loading the tool

Check nitrogen pressure regularly

Use OEM Beilite parts for replacements

English

English Indonesian

Indonesian