Nitrogen gas is the heartbeat of a hydraulic breaker. Stored in the accumulator and back head, it stabilizes the piston and amplifies impact force. However, because it is stored under extreme pressure, improper handling can lead to catastrophic equipment failure or serious injury.

This guide outlines the professional procedure for inspecting and charging nitrogen to ensure peak performance and operator safety.

1. Why Nitrogen Pressure is Critical?

Nitrogen acts as a “power assist” system. It absorbs recoil shocks and returns stored energy to the piston during the striking cycle.

- High Pressure: Can damage internal components and cause the breaker to “stutter” or fail to fire..

- Correct Pressure: Optimizes striking power, protects seals, and ensures impact stability.

- Low Pressure: Causes power loss, overheating, and accelerated internal wear.

- High Pressure: Can damage internal components and cause the breaker to “stutter” or fail to fire.

2. Essential Safety Rules

Before beginning, follow these non-negotiable safety protocols:

Depressurize: Completely release all gas before disassembling any cylinder or removing through-bolts.

Orientation: Always lay the breaker horizontally on the ground.

No-Go Zone: Never stand in front of the chisel. Pressure changes can cause the tool to eject or bounce suddenly.

Gas Type: Use Pure Nitrogen (N2) only. Never use oxygen or compressed air; they can cause internal explosions when mixed with hydraulic oil.

3. Required Charging Tools

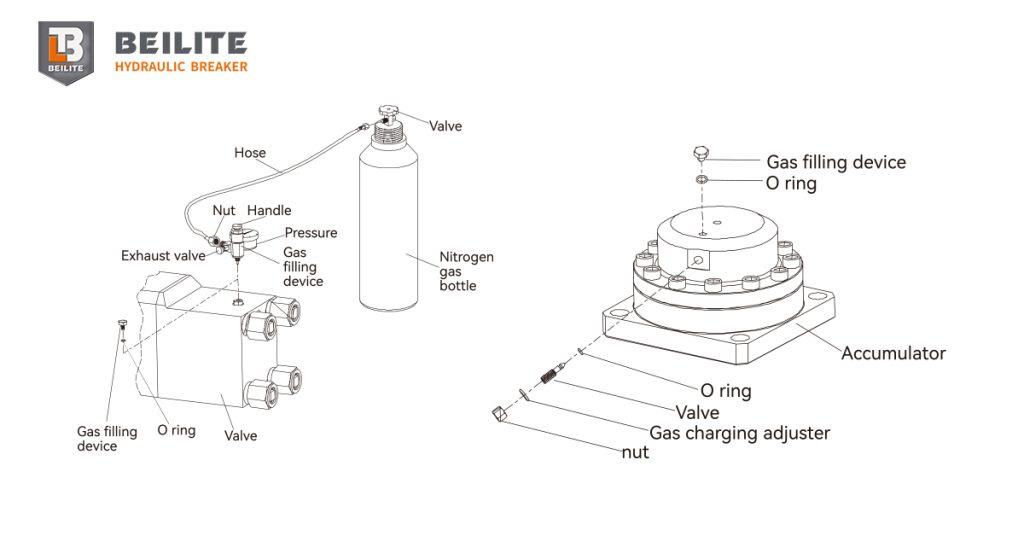

Ensure you have a complete Nitrogen Charging Kit, which typically includes:

- Spare O-rings and tightening wrenches.

- High-pressure charging hose and Nitrogen bottle.

- Pressure gauge and gas filling device.

- Exhaust valve and gas charging adjuster.

4. Step-by-Step: Charging the Back Head

The back head controls the primary striking force of the piston.

- Access: Remove the charging valve plug.

- Connect: Ensure the filling device handle is in the upward (released) position. Screw it firmly onto the charging valve.

- Measure: Depress the handle to read the current pressure.

- If High: Slowly open the exhaust valve to bleed gas to the standard level.

- If Low: Connect the hose to the Nitrogen cylinder. Open the cylinder valve in short, controlled bursts until the gauge reaches the target pressure.

- Finish: Close all valves, release residual gas from the tool, and securely tighten the valve plug.

5. Step-by-Step: Charging the Accumulator

The accumulator dampens pressure spikes in the hydraulic lines.

- Prep: Remove the charging adjuster nut and tighten the internal adjuster.

- Attach: Secure the filling device to the accumulator valve.

- Check: Slowly loosen the gas charging adjuster to see the pressure reading.

- Adjust:

- To Decrease: Use the exhaust valve to slowly vent excess gas.

- To Increase: Connect the filling pipe and add gas in stages, monitoring the gauge constantly.

- Secure: Tighten the adjuster, vent the device, and replace all protective nuts.

6. Nitrogen Gas Maintenance Matters?

Consistent nitrogen gas inspection and charging keeps your hydraulic breaker powerful, stable, and safe. Proper gas pressure protects critical parts like the piston, seals, accumulator, and back head. It reduces downtime, improves breaking efficiency, extends service life, and lowers total maintenance costs. For construction, demolition, mining, and quarry operations, this small maintenance task makes a big difference in productivity and safety.

7. Summary of Benefits

Regular nitrogen maintenance is not just a task, but it’s an investment. Consistent monitoring ensures:

- Maximum Impact Force: Keeps the breaker hitting at full capacity.

- Longevity: Reduces stress on the piston, seals, and back head.

- Cost Savings: Prevents expensive downtime and emergency repairs.

FAQs

1. Why use nitrogen instead of compressed air?

Nitrogen is dry and stable. Compressed air contains moisture and oxygen, which cause internal corrosion and risk combustion under high pressure.

2. How often should I check the pressure?

Check it weekly or whenever you notice a drop-in impact power or an increase in unusual vibration.

3. Can I overcharge the breaker for more power?

No. Overcharging will likely prevent the piston from cycling correctly and can rupture seals or damage the main valve.

Would you like me to help you create a specific “Nitrogen Pressure Chart” for the BEILITE BLT-series models we discussed earlier?

Keywords:

Hydraulic breaker nitrogen charging, hydraulic breaker maintenance, nitrogen gas for hydraulic breaker, hydraulic breaker gas filling procedure, excavator breaker maintenance, hydraulic hammer nitrogen pressure, accumulator nitrogen charging, back head nitrogen filling, hydraulic breaker safety tips, nitrogen gas inspection, how to charge nitrogen in hydraulic breaker, safe nitrogen gas filling for hydraulic hammer, hydraulic breaker accumulator pressure check, step by step nitrogen charging process, hydraulic breaker troubleshooting low pressure, construction equipment maintenance, excavator attachment care, hydraulic hammer performance, breaker accumulator service, hammer breaker gas nitrogen, jobsite equipment safety

Beilite Machinery Co., Ltd.

40008-40008

info@beilite.com

+6282321982255

English

English Indonesian

Indonesian