A hydraulic breaker also called a hydraulic hammer is one of the most powerful attachments you can add to an excavator, backhoe or loader. From breaking reinforced concrete to demolishing rock layers, a hydraulic breaker dramatically improves efficiency on any construction, quarry, or demolition site.

But like any high-impact tool, hydraulic hammers must be used correctly. Improper operation can lead to overheating, premature wear, piston damage, chisel breakage, hydraulic system failure, and even dangerous accidents.

This guide explains to all operators, constructors and technicians the right way to use a hydraulic breaker with practical, by following experts instructions to ensure safer, more efficient, and longer-lasting operation.

Warm Up Your Excavator / Backhoe / Skid Steer Loader Before You Start

Before activating the hydraulic breaker, always allow the excavator to warm up ideally for 10 minutes, especially in cold weather.

Why warming up your carrier machine is matters:

- Cold hydraulic oil flows slowly.

- Warm-up stabilizes hydraulic pressure.

- It prevents sluggish operation and reduces internal stress on the breaker.

A properly warmed-up excavator ensures the rock breaker delivers smooth, stable, and efficient impact force from the very first strike.

Select the Right Engine Speed for Hydraulic Breaker Operation

Many operators mistakenly believe that increasing engine speed (RPM) increases rock breaker power. In reality, excessive RPM does not boost the hydraulic hammer’s striking force. Instead, it causes problems such as:

- A rapid increase in hydraulic oil temperature

- Loss of lubrication capacity

- Reduce or decrease impact energy

- Possible piston damage

- Malfunction of the control valve

For safe and effective operation, always follow the manufacturer’s recommended engine speed. A moderate, stable RPM produces the best striking efficiency and prevents overheating.

Apply Hydraulic Hammer Breaker Correct Vertical Pressure

Proper downforce is essential for hydraulic breaker safety and performance.

Pressure must be applied directly along the chisel’s vertical axis, with the excavator’s front crawler or wheel slightly lifted.

If pressure is too low:

- Impact force is not fully transmitted.

- Energy rebounds into the excavator boom and hammer housing.

- The piston may “mis-hit,” causing dangerous blank firing.

If pressure is too high:

- The excavator tilts forward.

- The hydraulic breaker housing may collide with the material.

- Excessive stress may damage the rock breaker and boom.

Maintaining the right pressure ensures maximum impact efficiency and protects the internal mechanism.

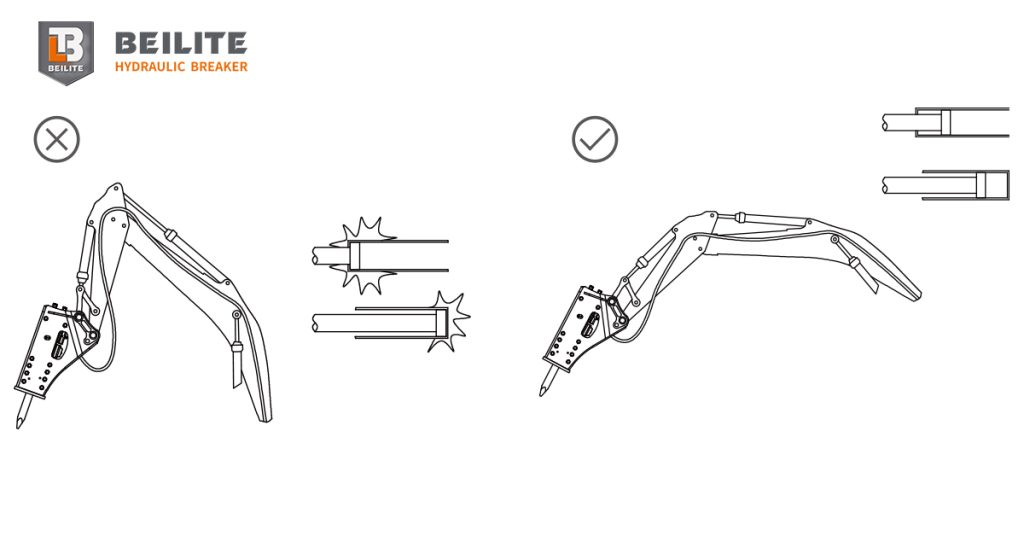

Ensure Hydraulic Rock Breaker Strictly Vertical Operation

Always keep the chisel perpendicular to the surface of the material being broken.

Inclined or angled striking causes:

- Sliding of the chisel

- Lateral stress on the piston

- Faster wear or fracture of the chisel

- Damage to the front head and housing

Vertical striking is one of the most important rules in hydraulic breaker operation. It prevents side-loading forces, which are the top cause of premature failure.

Do Not Strike Hydraulic Hammer the Same Point for More Than 1 Minute

Hydraulic breakers are built for impact not for grinding or drilling.

If a point does not break after 60 seconds, move to another position.

Continuous striking on a stubborn spot causes:

- Overheating

- Annealing or mushrooming of the chisel tip

- Increased wear

- Loss of efficiency

- Hydraulic oil temperature rise

- Damage to the breaker and excavator

For large or hard materials, always begin breaking from the edges instead of the center. This makes the job faster and safer.

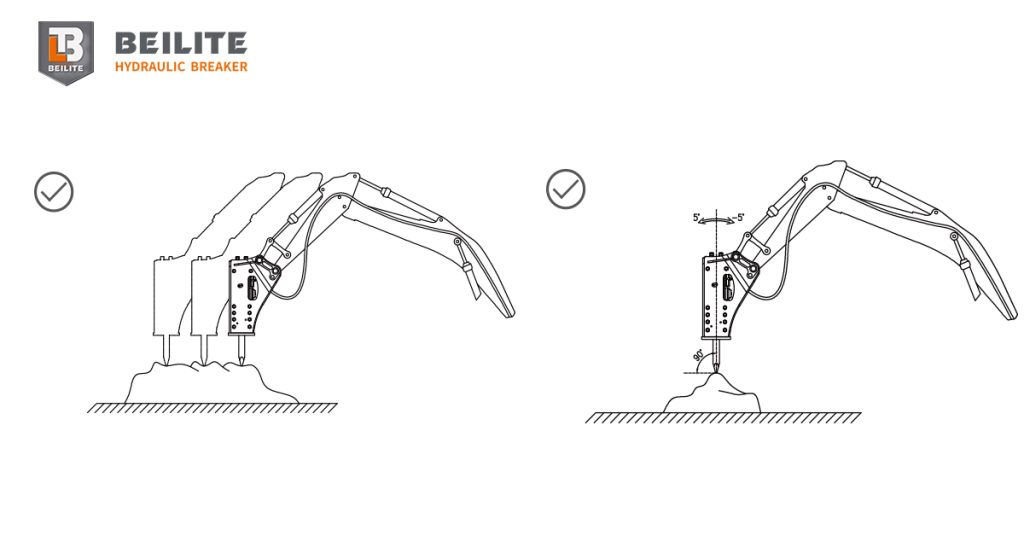

Use Proper Chisel Handling and Limited Swing Angle

During operation, the excavator breaker can be slightly swung forward and backward to remove dust beneath the chisel. However, the swing angle must never exceed 5 degrees.

Why?

A wide swing angle places dangerous bending stress on the chisel, often leading to chisel breakage.

Dust accumulation also reduces impact energy, so gentle movement is fine but never use the attachment breaker as a prying tool.

Never Use the Hydraulic Hammer /Breaker as a Lever or Sledgehammer

Hydraulic breakers are designed for vertical impact not prying, lifting, or pushing.

Never do the following:

- Leveraging the chisel to move rock or concrete

- Pushing materials with the breaker

- Lifting heavy objects using the chisel

- Using the breaker as a manual hammer to knock or pound objects

These actions can damage the bracket bolts, housing, and chisel—and may even crack the excavator boom.

Avoid Underwater Use Without Proper Equipment

Standard hydraulic breakers are not designed for underwater use.

If water enters the impact chamber between the piston and chisel, it can cause:

- Severe corrosion

- Loss of lubrication

- Seal failure

- Damage to the entire hydraulic system

If underwater operation is required, special submersible breaker kits must be installed. Or Beilite Underwater Hydraulic Breakers Are Required, Please Contacts Customer Service.

Avoid Extreme Cylinder Positions of The Hammer Breaker

Do not operate the hydraulic breaker when the excavator boom, arm, or bucket cylinder is at its extreme limits. Extreme positions weaken mechanical control, increasing the risk of structural damage to both the excavator and the breaker.

Prevent Blank Firing

Blank firing occurs when the chisel is not in full contact with the material—often after it punches through thin concrete or when striking loose rock.

Blank firing can severely damage:

- The piston

- The cylinder

- The chisel

- Internal breaker seals

Always monitor the sound and vibration of the breaker. If blank fire occurs, stop immediately and reposition the chisel.

Summary

Using a hydraulic breaker, the right way ensures safety, efficiency, and long-term durability. Whether you’re breaking concrete, rock, or asphalt, following correct operating techniques protects your investment and dramatically reduces machine downtime. Warm up the excavator, maintain vertical pressure, avoid extreme angles, use the right RPM, and never rely on the breaker for tasks it wasn’t designed for.

A hydraulic breaker is a powerful tool operate it with care, and it will deliver exceptional performance on any construction or demolition site.

FAQs

1. What should I do if the hydraulic breaker is not working properly?

If the hydraulic breaker isn’t functioning as expected, first check the pressure settings and ensure the chisel is properly aligned. Overheating or improper pressure can prevent effective operation. Always verify that the hydraulic oil is clean and the system is free of blockages. If issues persist, inspect for worn-out parts like the chisel, front head, or thrust bush. In case of mechanical failure, it’s important to stop the operation immediately and consult the manufacturer’s guide or a professional technician for further troubleshooting.

2. How can I prevent wear and tear on the hydraulic breaker’s chisel?

To minimize wear and extend the life of your chisel, always ensure it is used at the correct vertical angle to avoid lateral stresses. Never apply excessive force by hitting the same spot for over a minute. When breaking hard materials, start from the edges, as this reduces strain on the breaker. Regularly inspect the chisel for signs of wear, and replace it when necessary to maintain optimal performance.

3. Is it safe to operate a hydraulic breaker underwater?

No, operating a hydraulic breaker underwater without specialized equipment is not safe. Water entering the impact chamber can cause corrosion, loss of lubrication, and damage to the seals and hydraulic system. If underwater use is necessary, ensure that the appropriate submersible hydraulic breaker is installed to prevent these issues.

4. How do I avoid blank firing with the hydraulic breaker?

Blank firing occurs when the chisel strikes an empty or unsuitable surface, such as thin concrete or loose rock. This causes the impact force to rebound, potentially damaging internal parts. To avoid blank firing, always ensure the chisel is in full contact with the material. Pay attention to the sound and vibration of the breaker, if you notice irregularities or the breaker is struggling to make an impact, stop and reposition the chisel for a more stable contact.

Beilite Machinery Co., Ltd.

40008-40008

info@beilite.com

+6282321982255

English

English Indonesian

Indonesian