Beilite Indonesia delivers advanced hydraulic hammers engineered for all major global carrier brands—from mini excavators to heavy-duty demolition machines. Our hydraulic breakers perform reliably in underwater operations, extreme cold or high-temperature environments, and on the toughest materials. Backed by international certifications and recognition from EDA, AEM, and ISO, Beilite provides professional, durable, and high-performance solutions for every application. BLTB-280-5-W-AC15 won 2025 World Demolition Award.

Founded in 2002, Beilite Machinery Co., Ltd. is a global leader in hydraulic breaker manufacturing, offering three premium product lines: sound surpressed, side-mounted, and top-mounted models. Engineered for extreme conditions—including cold climates, intense heat, underwater operations, and hard material applications—Beilite pioneered China's first heavy-duty and underwater hydraulic breakers.

Beilite comprehensive BLT40–BLT280 series accommodates carriers ranging from 0.5 to 350 tons. Beilite commands over 50% market share for heavy duty breakers, and our BLTB-280-5-W-AC15 won the 2025 World Demolition Award for Innovation , designed for excavators 100-350 tons as the world heaviest hammer.

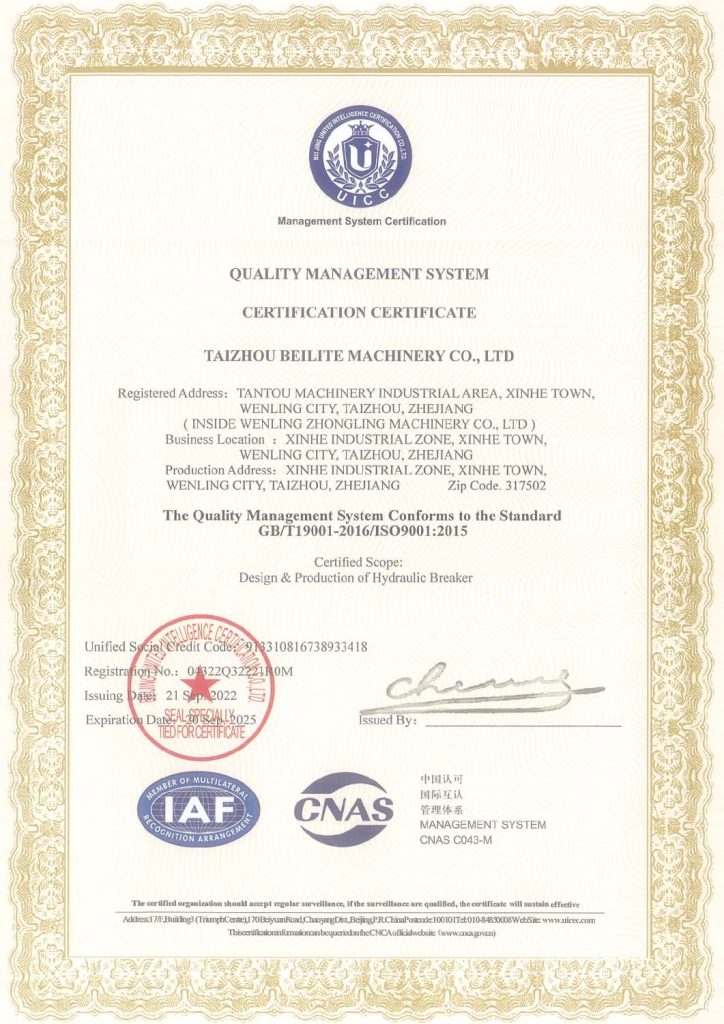

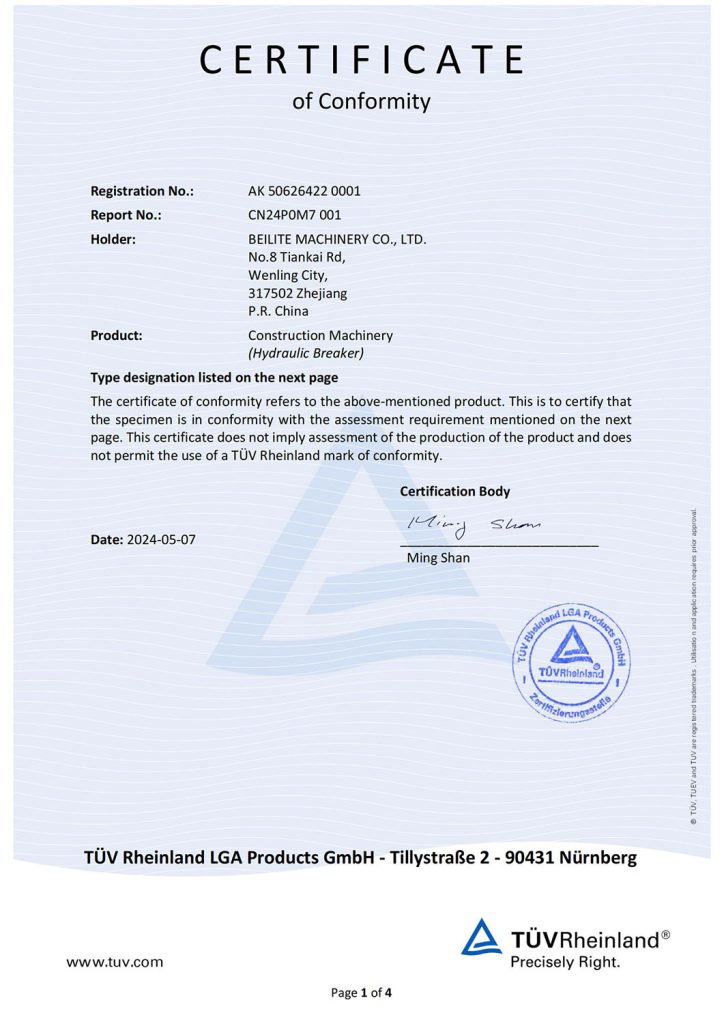

Backed by hundreds of international patents, ISO 9001/14001/45001 certifications, and memberships in the European Demolition Association (EDA), Association of Equipment Manufacturers (AEM), Beilite products are trusted in 100+ countries, including the United States, Germany, and Australia.

Beilite Subsidiaries Indonesia branch, located on Pantai Indah Kapuk Street in North Jakarta City, has sold over 1,000 premium breakers along with a wide range of spare parts by 2025. Our local expert team provides professional consultations, product function demonstrations, and tailored solutions for all application types. The branch regularly organizes comprehensive product exhibitions to showcase Beilite's latest innovations and technological advancements.

Fully enclosed housing with damping materials to reduce noise and vibration. Ideal for urban construction, residential areas, and noise-restricted job sites. Provides stable operation and protects internal components from dust and debris.

Open frame design with mounting brackets on the side of the hammer breaker body. Delivers strong impact energy with easy maintenance access. Commonly used in quarrying, mining, road construction, and general demolition where noise control is not the main concern.

Bracket positioned at the top of the breaker, allowing vertical and direct power transfer. Offers higher impact efficiency and better penetration force. Preferred for heavy-duty demolition, tunneling, and hard rock breaking.

With over 70 internationally advanced precision machines (including DMG, MORI, and DOOSAN), every Beilite component is manufactured with exceptional accuracy and consistency, ensuring unmatched quality and reliability in every product.

Delivery within business days for stock items, and within 7–14 days (excluded weekend and holidays) for customized manufacturing orders (within 20 days). For more details, please contact Beilite’s authorized agents or factory to inquire about product availability, delivery schedules, and pricing options.

Our hydraulic breakers are state-of-the-art tested facilities ensure that every product undergoes rigorous precision and performance checks, guaranteeing superior durability, reliability, and quality before it reaches you.

Beilite hydraulic breakers are built for power, precision, and reliability. Designed with advanced technology and high-quality materials, they deliver superior performance in mining, construction, and demolition projects. With low maintenance costs, long service life, and global support, Beilite ensures maximum productivity and value for every operation.